Rammstein Tour

Dart Rigging Has Turned To The RSM System To Monitor The German Rock Band’s Growing Rig Since 2009 - 2013

German metal band Rammstein's longevity on the touring circuit is often attributed to the band’s over- the-top live shows, a combination of driving rock and stage theatrics that appeal to fans on both sides of the Atlantic.

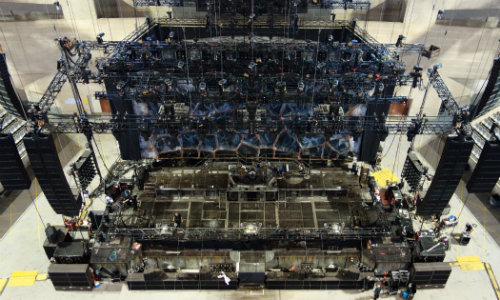

Because Rammstein shows have grown in complexity over the years, with today’s typical show a 20 truck pull with 50 tons of gear to manage, the sheer weight of the rig, most of it flown high above the band, crew and audience, not to mention the moving dynamics involved, makes load safety an ever important issue.

Increasing weight

Germany-based Dart Rigging GmbH has been handling rigging on Rammstein shows since 2005 and for the band’s last two tours has been using Ron StageMaster wireless load cells by Eilon Engineering to monitor the large set up and any overload issues.

"Rammstein rigs continue to get increasingly complex," states Dart co-owner Martin Gehring, who served as head rigger on Rammstein’s 2009-2011 "Liebe ist für alle da" tour, as well as the 2011-2013 "Made in Germany" tour, which ended in August.

"When you take into account the automation systems, custom set elements like the special bridge we had for the latest tour and the band’s famous logo-cross, and then add in the lighting pods and sound equipment, it’s a lot of weight to worry about."

Martin got involved already in the tour’s design phase by creating a technical design of the flown rig that allowed the show’s lighting and set designs to become reality. “By creating the truss layout and calculating the weight distribution, I decided where we needed 1 ton or 2 ton motors and also if and where we needed load cells in the grid,” he says. “When it comes to a truss system with multiple motors and shifting loads because of sub-hung moving objects like on Rammstein, load cells were a must.”

The “Made in Germany tour” included a lot of moving elements with a mother grid flown across an astounding 120 motors, 42 of which were in key positions and equipped with Ron StageMaster load cells.

“Show loads used to typically be around 20-30 tons but today it’s not unusual to have loads around 50 tons, yet the venues are the same,” Martin comments. “That means there is less headroom with the weight. You need to be sure the weight you’ve stated in the plot is correct and you often need to prove it to a venue engineer. Load cell monitoring is the way to do it. Load cells give you the proof.”

Value of load monitoring

For their latest two tours, Rammstein has basically been on the road since 2009 and has used the Ron StageMaster load cells at a huge variety of arenas and festivals in both Europe and North America. As one of the more experienced riggers in the industry, Martin knows the value of a reliable load monitoring system. He comments, “To be able to control the weight every day also helped us to get approval for smaller venues from house engineers where we were very close to the overall weight capacity of the roof. It’s definitely easier to talk to the building engineer when they see you use load monitoring. You can feel their relief when they see that the show does what it says it will. It has definitely made my work easier.”

Martin also says that Dart is increasingly asked by venues in Germany to use their RSM system to measure loads when other tours and events come into town.

Ron StageMaster 6000

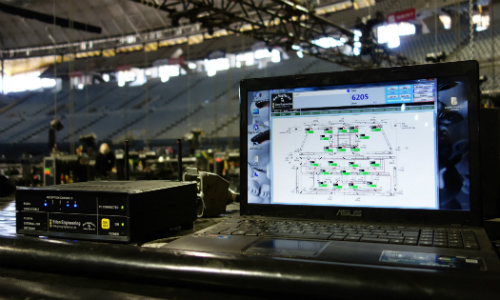

Dart was one of the first users of the Ron StageMaster wireless load cell system in the touring market and on Rammstein’s “Made in Germany” tour turned to Eilon’s award-winning Ron StageMaster 6000 G4, which can accommodate a virtually unlimited number of load cells. On this tour, Martin used it to monitor 42 wireless load cells from a laptop.

“With lots of motors to manage and a dynamic rig overhead, weight can shift unpredictably,” Martin states. “Using the RSM 6000 was a very safe way to make sure that the mother grid was leveled right for every show so that the weight distribution mirrored what we had in our rigging plot. It is obvious that when it comes to a large grid with dynamic loads there is no way that you can just level it by using tape measures. The weight distribution would be different each day.

“The system is easy to install, which is essential when you are out on tour, and the wireless communication between the load cells and the laptop doesn’t require a messy network of cables. When loading in, we just switch it on, set up the receiver and computer and watch as the load goes up. We level it to make sure it is the same as the plot and put in an overload limit and receive a signal if it is exceeded so that I can take action. It’s as easy as that.”

Martin monitored the Rammstein rig from a laptop in real time with the RSM software allowing him to overlay the load map onto the plot on screen, making it easy to see where motors, weight, etc. were on the plot. “It’s a good visual and then the system also provides a record at the end of the show that I can review to see if there was anything I need to be aware of,” he says.

Peace of mind

RSM systems include a host of safety features like a transmission distance of up to 1 km and a 4000-hour battery life with no sleep mode that can compromise safety. Tracking errors are also a non-issue as Eilon uses three frequencies instead of just one to guarantee that contact is never lost to the load cells, and the system works even when other wireless systems are in use.

Eilon, which has been in the market for 30 years with industrial load monitoring systems in use for clients like NASA, Boeing, the USAF, Lockheed Martin, GE, Siemens and Rolls Royce, brought the technology to the entertainment world 10 years ago. RSM systems are used around the world by prestigious clients such as the Sydney Opera, Casa da Musica Portugal, Esplanade Theatres on the Bay- Singapore, Munich Olympia Park, Swiss TV, Seattle Opera, Orange County Convention Center, Tait Towers, Shimizu Octo Japan, Royal Shakespeare UK and many others.

Dart was one of the first adapters, purchasing their first RSM system in 2005. “We’ve used the RSM product for a long time,” Martin concludes. “It’s a type of insurance and at the end of the day gives peace of mind. We are very satisfied not only with the Ron StageMaster load cells we own but even more with the good support and constant development from Eilon Engineering.”

For more information please contact your local Eilon representative or Noga Eilon-Bahar at:

E-mail: neb@eilon-engineering.com

Mobile: + 972-528-901851

Office: +972-4-8577720

Web: www.eilon-engineering.com

.jpg)